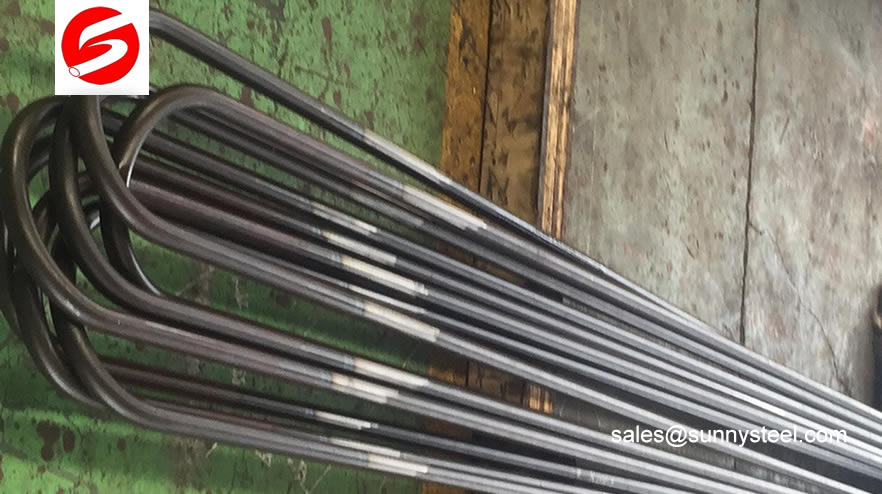

We bend ASTM A179 U Bend Tubes with round, rectangular, square, plus oval cross sections used in medical, automotive, plus electronics industries.

ASTM A179 U-Bending tubes are widely used in Heat-exchangers.

ASTM A179 U Bend Tubes for heat exchangers applied mostly in oil and gas plants, chemical and petrochemical plants, refineries, power plants and renewable energy plants. Low fin tubes can be supplied in the form of U bends.

U-bent tube sizes (u-bending, u-bend)

Heat treatment of U bent tubes

Post bending heat treatment by electrical resistance (Joule effect) is applied. The temperature is monitored and controlled during the process. It is possible to perform the heat treatment in a nitrogen atmosphere.

U bent tubes can be tested as follows

All materials are hydro-tested as standard. Stress relieving is carried out in a gas-fired furnace or solution annealed using an induction heat process. We can offer a range of additional testing on request, including dye penetrant and PMI testing.

- Hydrostatic Test

- Air Underwater Test

- Pulsating Pressure Test

- Dye Penetrant Test

- Magnetooptical Test

Bending Type:

Cold Bending and Hot Bending.

Heat Treatment:

After Cold Bending, the bending area needs heat treatment.

- Object medium: 10% sodium

- hydroxide+5% sodium hypochlorite

- Shell Diameter: ø 800

- Working Pressure: 1.5mpa

- Working Temperature: 40º C-90º C

- Heat Exchange Surface Area: 100M2

- Material: Gr1\Gr2

Comments